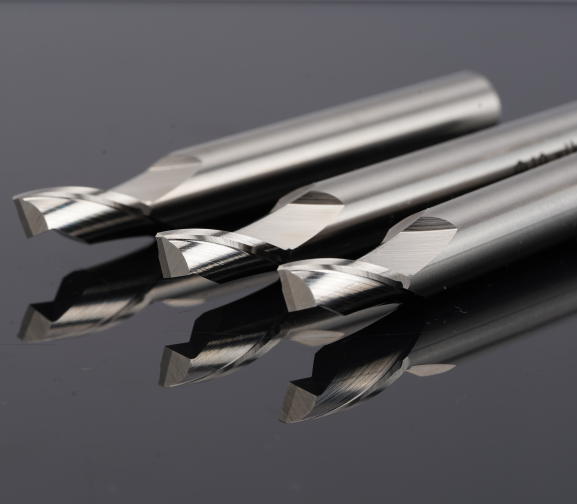

1F end mills also named single flute end mills or single blade end mills, which is an end mill with only one main cutting flute. It is mainly used for processing light-weight metal materials. It can not only be used to process planes, through holes and blind holes, but also can be used for boring.

Classified by raw materials:

Carbide 1F end mills

HSSPM 1F end mills

HSSCo 1F end mills

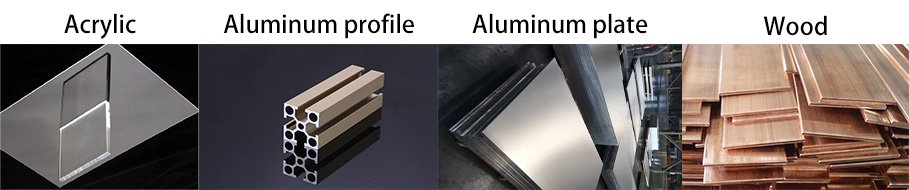

What workpiece material to work for?

Solid Carbide Single Flute End Mills: The flute type can be designed to process acrylic, wood, aluminum plate, aluminum profile copper and gold etc.,

HSS PM Single Flute End Mills: The flute type can be designed to process aluminum plate and aluminum profile

HSS Co Single Flute End Mills: The flute type can be designed to process aluminum plate and aluminum profile

Prcossing Application

The milling cutter is specifically designed for high-speed cutting of aluminum,copper and gold etc,with excellent finish.

Carbide fresa with 1 flute

Compatible machines: Engraving machine, Small engraving machine, CNC machining center, computer shaving machine, horizontal milling machine,vertical milling machine,etc.

Applicable materials: PVC, acrylic, plastic, resin, leather, nylon, cork, aluminum profile, aluminum alloy doors and windows, aluminum plastic doors and windows, aluminum alloy curtain walls, gold, copper, etc.

Which industries can be applied to?

Carbide 1F Endmill For Acrylic and Wood

Carbide 1F Endmill For Curtain Wall

Carbide 1F Endmill For window and door

HSS fresa with 1 flute

Compatible machines: Engraving machine, Small engraving machine, CNC machining center, horizontal milling machine,vertical milling machine,etc.

Applicable materials: aluminum profile, aluminum doors and windows, aluminum curtain walls, etc.

HSS 1F Endmill For Curtain Wall/Aluminum window and door

Characteristics of 1F milling bits from SZSUNLIT

Carbide: Using mirror sharpening technology for flute, the cutting edge is sharp and wear-resistant, high-speed cutting with smooth finish performance, large chip flute design, smooth chip removal, no sticking to the end mill, no smoke, no burrs when high speed working,can be dry cut

HSSCO/PM: Especially suitable for medium and low speed precision machining technology of new and old machine tools. Sharp and wear-resistant, not easy to break when working,it must be cooled during processing

Comparison of characteristics of cemented carbide single-edge milling cutter and high-speed steel single-edge milling cutter.

COST

HSS: Cost-effective

Tungsten steel: the price of end mills is higher than HSS, but suitable for high speed cutting and the life span is much higher

WORKPIECES

HSS: aluminum

Tungsten steel: more workpiece material can be machined

EQUIPMENTS

HSS: general

Tungsten steel: high precision and small vibration amplitude

PERFORMANCE

HSS: The hardness and thermal hardness are general, very sharp but wear-resistance is not good as carbide 1 flute fresa

Tungsten Steel: The hardness and thermal hardness are good, long life of end mills,but the toughness is not good as HSS