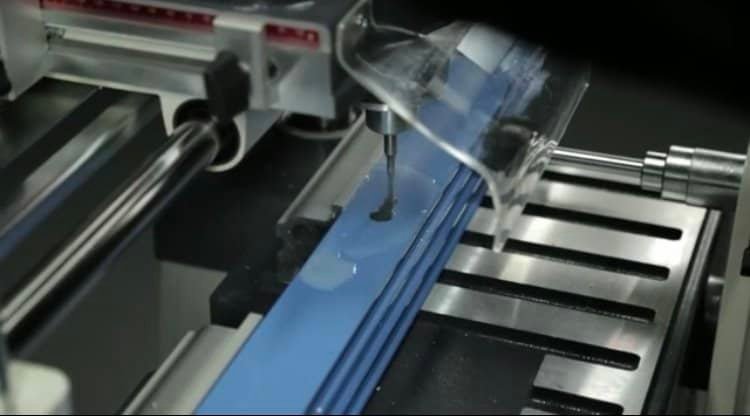

Customer’s Demand: straight down to slot drill in dry cutting condition, the end mills should be ware-resistant.

Workpiece material: Aluminum profile

Cutting tools used: Normal HSSCo/ Carbide 1F end mills (freezing bits)

Problem: the tools wear out quickly

Ask: Could you please design 3F end mills to work for slotting?

Solution:

- 3F Carbide End Mills with Tac coating: with pretty good wear resistance, but the feed could not be as fast as working for thick workpiece material when working. Because the aluminum profile is thin, may not be able to withstand such a large cutting force. Need to reduce feed.

- 1F Carbide End Mills with Tac coating: with sharp flute, the feed can be very fast, and Tac Coating can help to reduce wear and increase the life of the freezing bits.

Finally, which solution did the customer choose? And what is the testing result? If you would like to know, contact us freely!

Carbide End Mills 1 Flute good for alu. and curtain wall

Best Suitable materials :Aluminum

could also suitable for below materials:

1. MDF ,patticle board ,board with lagging ,log,affixed to skin panels

2. Acrylic ,PVC,resin ,plastic,chipbord,composite board ,melamine,

3. Solid wood ,native wood, plywood,lotus plate

<img class="alignnone wp-image-607" src="https://szsunlittools.com/wp-content/uploads/2020/09/图片1-11.jp…

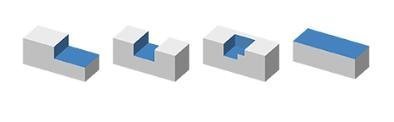

Carbide End Mills 3Flute for Aluminum

Best Suitable materials : Aluminum

could also suitable for below materials:

1. Aluminum alloy

2. Non-ferrous material

Features:

1. Designed for high speed machining aluminum, aluminum alloy and …