Are the end mills too durable a good thing or a bad thing? That is a question.

Customer A needed carbide end mills for Aluminum, the size is 3.0*4*9*50mm, need to process aluminum parts with excellent smooth finish.

At first, we introduced our “ Mirror Face” series end mills to them, the performance is as follows:

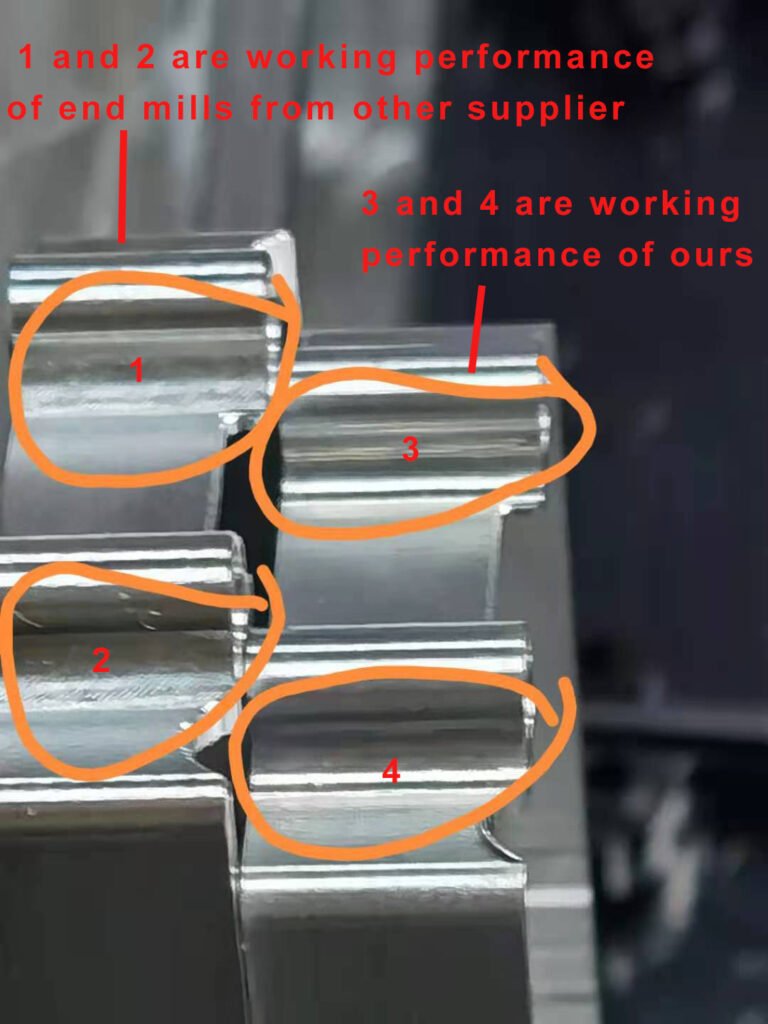

But after quotation, they could not afford the price of this type of end mills aluminum. So we quoted with another normal high finish series to them, they accepted the price and tested the samples. The following picture was the test result they sent to us. And then they started to place bulk order to us.

On 2021 June 17th , they requested slot milling cutter for aluminum, demanded the carbide end mill should be with good abrasion resistance and high finish. We introduced our 3F end mills with TAC coating. Then samples were testing, today we follow up the quality of the endmill cutters. They feedback “ They are really really excellent, the tools are still not broken. As you know, the end mills i bought from other supplier, the longest working life is 7 days. How exciting of your TAC tungsten carbide end mills, they keep working on 21days !”

Now here is a question: Our cutting tools are so durable, how long will customers come to repurchase? Oh, i need to explore more customers to complete my sales task!