The most amazing thing about machinery is that it brings great convenience to daily life. From cars to kitchen knives, do you know how their parts are processed? A group of moving pictures will show you the common methods of machining.

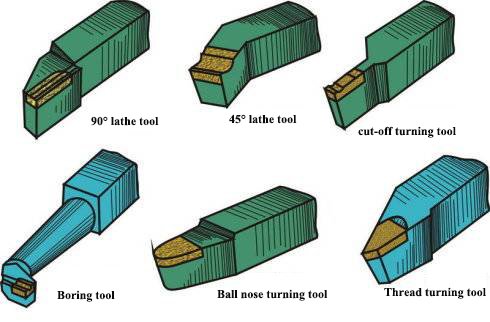

First, the workpiece is fixed on the machine tool by the chuck, and then the workpiece rotates at a high speed under the drive of the motor, and the speed can be controlled manually according to our processing requirements. Then, you can start to control the tool to sculpt on the surface of the workpiece, which is called “cutting”. Common turning tools are often made of high-speed steel or solid carbide. In recent years, ceramic tools and synthetic diamond tools on the market are also widely used. Different shapes of turning tools can meet various processing requirements:

In addition to the outer surface, the boring tool used in turning can also finish the inner surface where the workpiece has holes.

Milling

After talking about “turning”, let’s talk about “milling”. In fact, it still uses the rotating processing method, but this time it is milling cutter to rotate.

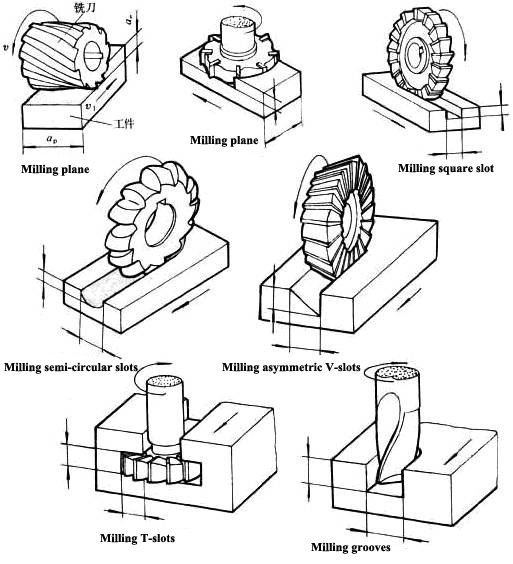

Traditional milling processing has two relative motion methods, one is like the above picture, the workpiece being processed is fixed, relying entirely on the milling cutter to rotate and translate by itself; the other is as shown in the figure below, the milling cutter does simply rotation, the workpiece can move in three directions: front and back, left and right, up and down.

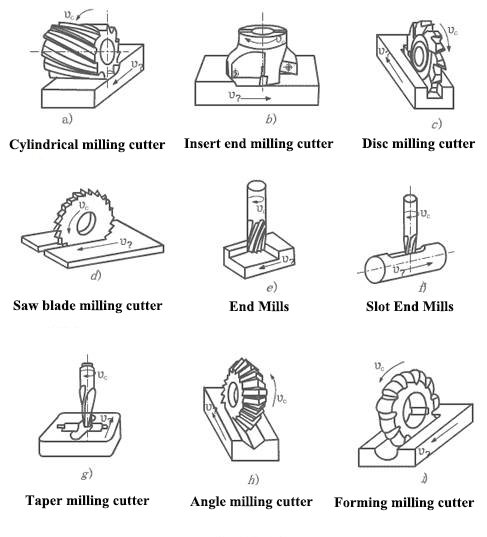

The milling cutter is a multi-flute tool. In each milling process, each cutting edge of the milling cutter only participates in one cutting, and the rest of the time is stopped to facilitate heat dissipation. In this way, the cutting efficiency of the milling cutter is higher than that of the single-edged turning tool. Milling cutters of different shapes can complete the processing of various planes, step surfaces, grooves and cavities. The amount of milling during working is composed of four elements: cutting speed, feed, back-cutting (milling depth) and side-cutting (milling width).

Several common milling processing methods

Several common types of milling cutters

Planing

The working principle of planing processing is clear at a glance. Simple reciprocating motion has extremely low production efficiency compared with turning and milling. However, because of the simple structure of equipment and tools, it is still used for rough processing of the surface of the workpiece.

Grinding

Grinding is the use of abrasive tools such as grinding wheels and belts to cut the surface of the workpiece. In today’s machining, the grinding head has been maturely integrated into the machining center of the CNC milling machine.

2 thoughts on “A few pictures show you the common methods of machining”

Having read this I thought it was very enlightening. Mathilda Waite Memberg

Just wanna comment on few general things, The website design and style is perfect, the subject material is really superb : D. Heidi Cy Frangos